Edge processing

Quick and economical high-quality glass arrissing

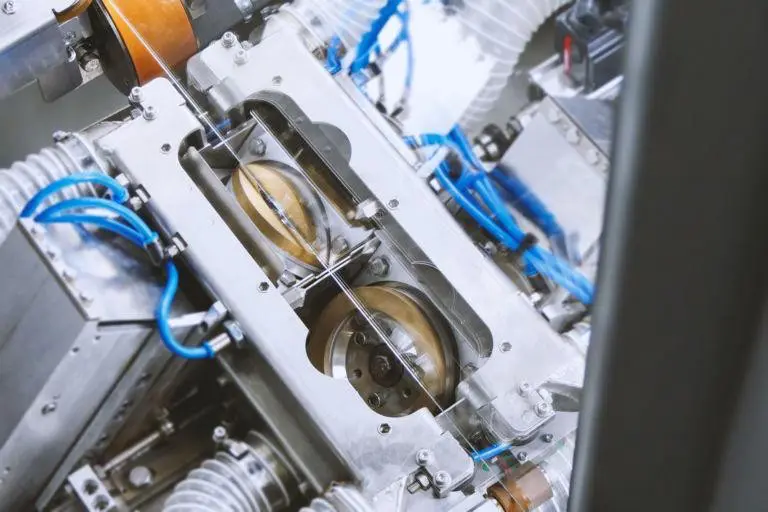

The 3in1 glass arrissing solution with cup wheel technology

1.

Versatile and flexible applications

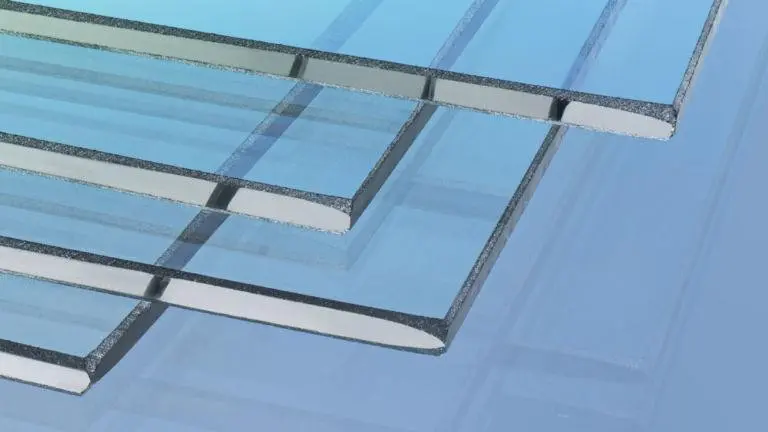

- Automatic arrssing of rectangular and shaped glasses

- Straight edges and radii – both possible

- Float glass, tempered glass and laminated glass

2.

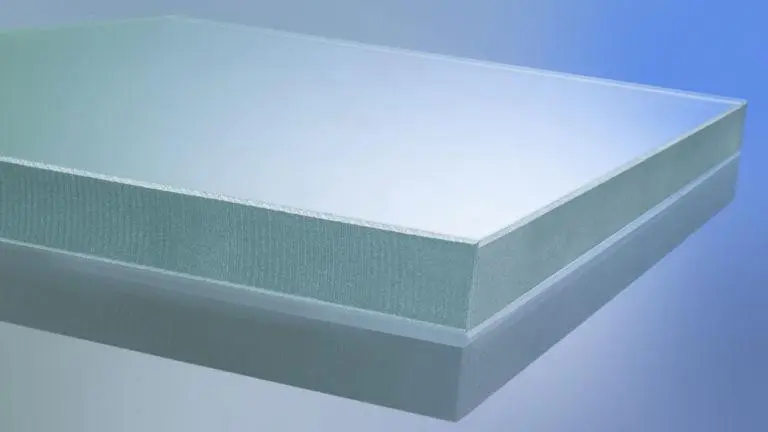

Homogeneous and uniform arrissing quality

- Edge arrissing

- Flat edge arrissing

- Corner dubbing

3.

Economical and accurate production

- Highest process speed up to 60 m/min (edge and flat edge)

- Low cycle times & operating costs

- No tool change with the cup wheel technology

MULTI'ARRISSER

Automatic vertical arrissing machine

Homogeneous and uniform arrissing quality even at the beginning and the end

- Best arrissing quality through the use of cup wheels.

- Compared to profiled wheels, the contact surface to the glass with cup wheels is much higher.

- Material removal is distributed over several diamonds and thus becomes more even.

Highest arrissing speed

- The cup wheels allow a maximum arrissing speed of 60m/min (also for flat edge).

- With these speed the MULTI’ARRISSER is the fastest single-head-machine worldwide.

No tool change necessary

- Always the same cup wheels are used for different glass plate thicknesses and different functions.

One cup wheel for multiple functions

- Different glass thickness from 3 mm to 25 mm

- Different functions such as edge, flat side, corner dubbing are realized with the same cup wheel

- No loss of production time in mixed operation

- Only one wear part

- Best price/performance ratio for the tool due to simplest geometry

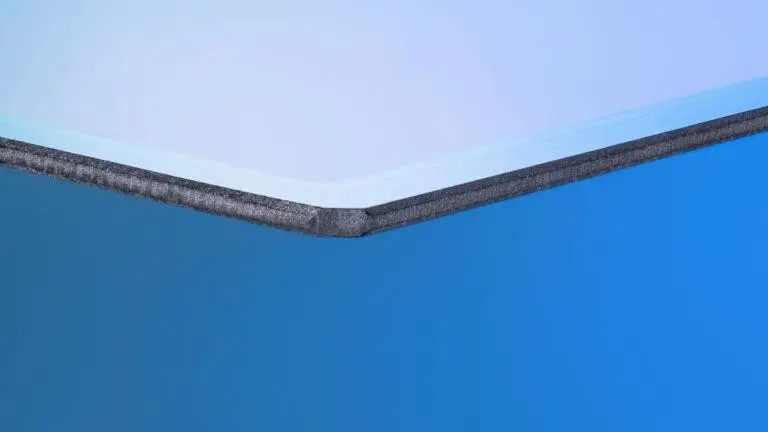

Long lifetime of arrissing tool

- 5 to 10 times higher lifetime for glass edge arrissing than all other arrissing systems

- Higher productivity due to higher uptime

- Less service interventions due to less shutdown time

- Possible cost reduction within a shortest period of time due to longer lifespan of the tools